Sliding Friction Tester

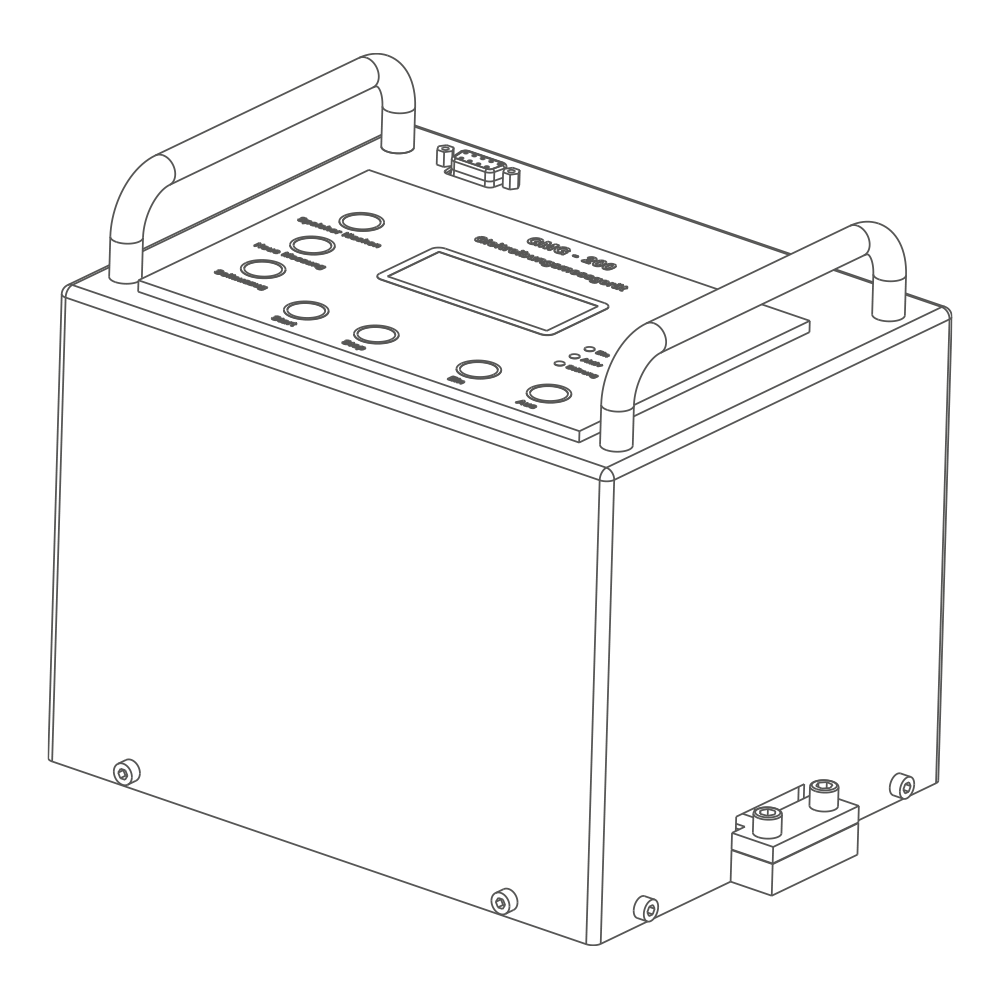

GMG-200

Floor coverings must be slip-resistant.

The mobile GMG 200 measures the coefficient of sliding friction of floor coverings according to the applied standards and specifications. This product is both easy to use and ideal for assessing slip hazards for pedestrians on-site.

Architects, builders, property owners and employers can use the GMG-200 sliding friction tester to assess the slip-resistant properties of floor coverings. GTE Industrieelektronik developed the measuring device in cooperation with the Berufsgenossenschaftliches Institut für Arbeitsschutz (BIA, German Professional Association Institute for Occupational Safety).

It is suitable for measurements to determine the coefficient of sliding friction of floor coverings in accordance with the standards EN 16165, EN 13893, ANSI NFSI B101.3, and DIN 51131. The GMG-200 is ideal for on-site floor testing. It enables users to assess the risk of slipping under current conditions in accordance with the publication of Germany's statutory accident insurance DGUV Information 208-041. This enables you to prevent falls and avoid insurance claims.

The device is placed and started on the test surface by the tester and then pulls itself over the surface to be tested on a glider at a constant speed specified in the standard. The GMG-200 then records the tensile force required for this, which depends on the coefficient of sliding friction of the floor. It records the values and calculates the average sliding friction value of the surface over 0.3 or 0.5 m, depending on the standard. The measurements should to be taken at representative locations on the ground. Five individual measurement runs must be recorded for each measurement series, and three of these five runs are then combined to form a test cycle. After the data is transferred to a PC, the GMG-Vision software then takes over the rest of the evaluation.

We are pleased to assist you.

Do you need general information on our measurement technology devices, would you like advice, are you interested in training courses on our measurement technology products or would you like to request a quotation? Contact us by phone at +49 2162 3703-0 or by e-mail (info@gte.de) or send us a non-binding contact request via our inquiry form.GTE Industrielektronik GmbH

Measurement Technology

Technical Data GMG-200

| Dimensions, handle included | 160 mm x 200 mm x 150 mm (L x W x H) |

| Measuring surface | 11,25 mm² |

| Weight | 10.000 g ± 100 g |

| Interface | RS-232 |