Sliding Friction Measurement

GMG Accessories

Good preparation with suitable accessories

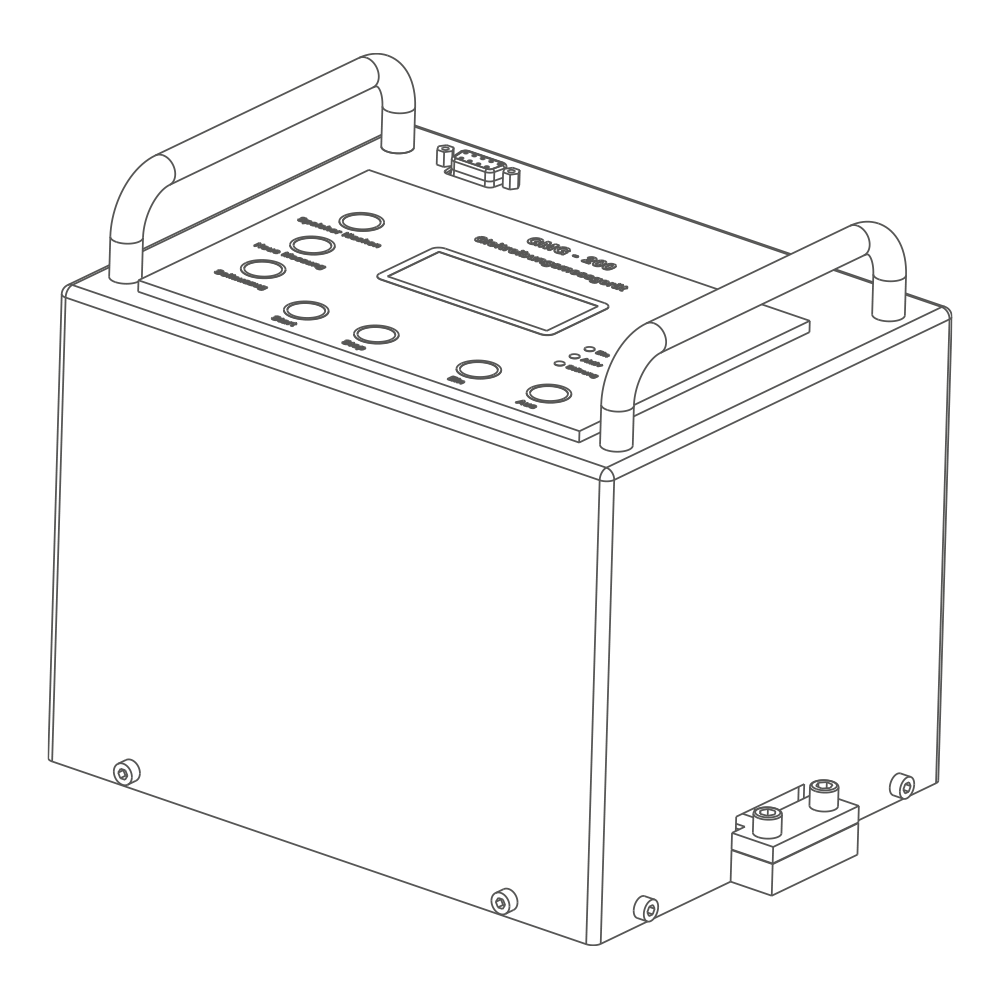

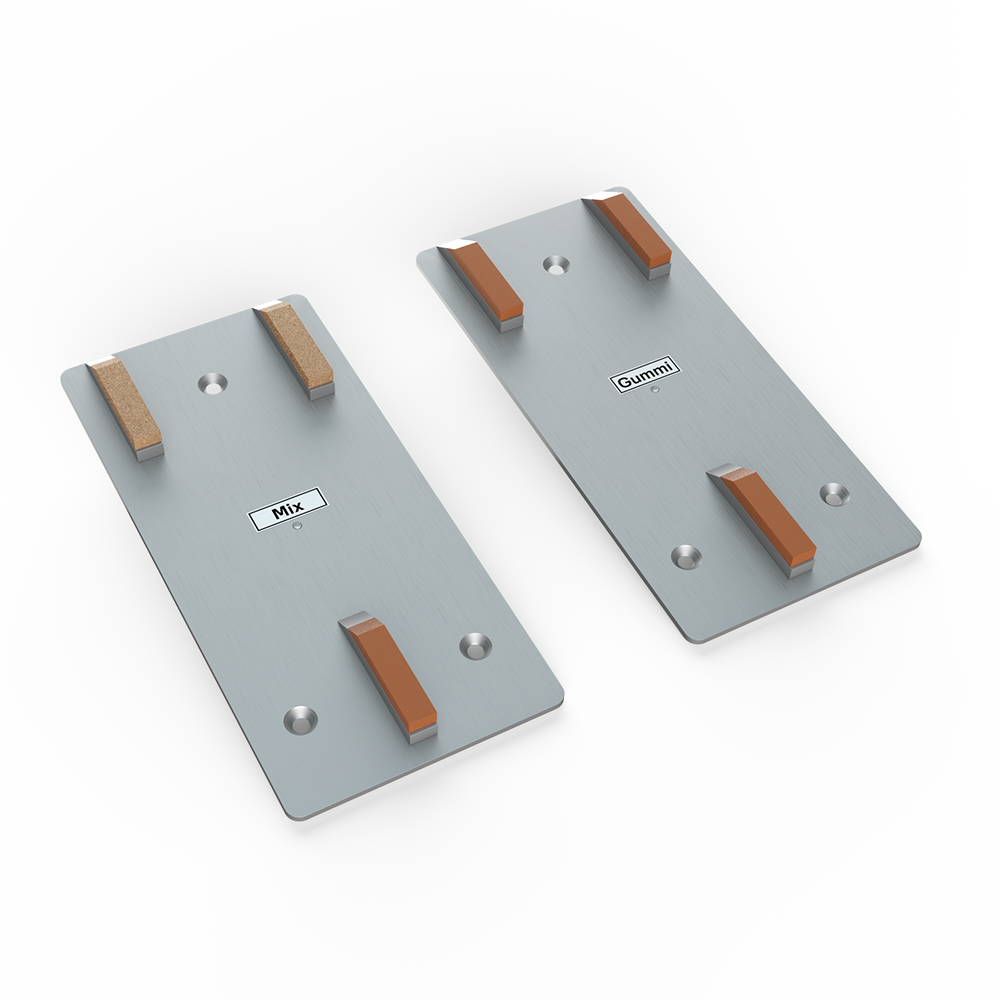

Standardized test equipment is used for sliding friction measurement in accordance with current standards and specifications (EN 16165, EN 13893, ANSI NFSI B101.3, and DIN 51131). The surfaces of the sliders must be ground flat before measurement. They are then clean and dust-free and have the specified, defined roughness. This condition must be met before each series of measurements to ensure accuracy. The GMG sandpaper is available as accessories for this purpose. Sliders and slider plates are available as spare parts.

Testing according to the situation

The user must test the flooring on site depending on the problem or operating conditions. This must be done in at least one or more of the following conditions:

- in the typical situation on site, i.e. in the operating condition determined there and with the slip-promoting substances present there,

- with a lubricant consisting of a 0.1% solution of sodium dodecyl sulfate (purity ≥ 99 %) in deionized or distilled water corresponding to our "SET-GMG Sodium lauryl sulfate ≥ 99 %".

- with other lubricants commonly used in operations,

- in the dry and cleaned condition of the soil.

The cleaning and care products, cleaning procedures and cycles used regularly on site should be noted.

Replacement sliders and replacement slider plates are available as accessories for the GMG-200 and obtainable with all standard-relevant slider materials. The slider plates are equipped with a sensor so that the GMG-200 can automatically recognize the existing slider material.

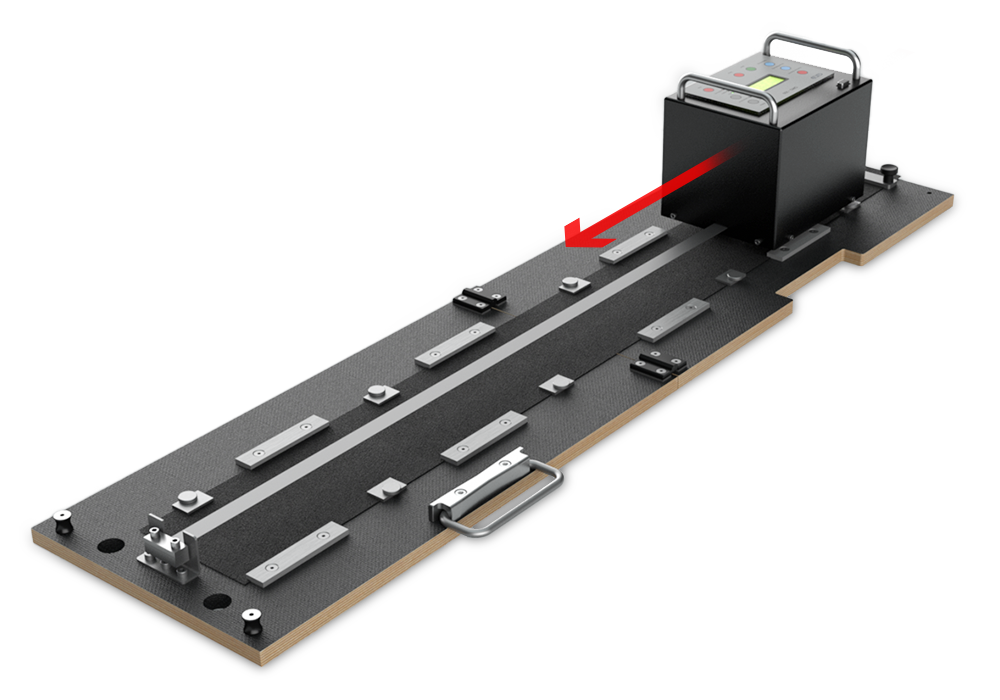

According to the current state of standardization, the GMG sliding friction tester must be dragged evenly over the GMG sandpaper in order to prepare the sliding material. The GMG-Carrier-Plate makes it very easy to comply with this requirement. The GMG sandpaper is fixed on the carrier plate over the specified length so that the GMG device can glide over it safely. The carrier plate can be folded up and is equipped with a handle. The sandpaper can remain in the guide rails until the next replacement. The GMG-Carrier-Plate replaces the GMG standard grinder.

To ensure a standardized measurement process with relaxed water, we recommend our "SET-GMG sodium lauryl sulfate ≥ 99%". This enables a 0.1% solution of relaxed water to be produced as a lubricant from one gram of pellets and one liter of deionized or distilled water.

The "SET-GMG sodium lauryl sulphate ≥ 99%" contains 250 g pellets made from sodium lauryl sulphate, a dosing aid measuring 1 g and a transport can for measured quantities.

GTE Industrieelektronik GmbH offers standard sandpaper for a mandatory preparation of the slider surface. The rolls are coated with silicon carbide abrasive.

We are pleased to assist you.

Do you need general information on our measurement technology devices, would you like advice, are you interested in training courses on our measurement technology products or would you like to request a quotation? Contact us by phone at +49 2162 3703-0 or by e-mail (info@gte.de) or send us a non-binding contact request via our inquiry form.GTE Industrielektronik GmbH

Measurement Technology