Industry Solutions

Fire Detection in Recycling Plants

As versatile as recycling plants and the materials to be processed there are, as complex and wide-ranging are the hazards. Our extensive product range of ADICOS fire detectors covers a wide variety of challenges here: harsh ambient conditions and interference, bulk material or moving sources of danger – right up to the risk of explosion. We advise our customers from the recycling industry and develop detection concepts together with them.

Monitoring recycling facilities with their typical open-air warehouses, large halls, shredders and storage boxes is challenging. Harsh conditions caused by dust, exhaust fumes, dirt, humidity and fog make work difficult. Added to this are heat buildup, embers, heat and flying sparks. Fire gases and other gases also occur.

Despite clearly defined specifications for pre-sorted recycling material, dangers cannot be ruled out: The delivered material may already contain embers. Improperly disposed objects may also be present, which ignite when exposed to mechanical impact. Based on experience, we recommend monitoring at all stations – from delivery to removal.

Increased Dangers

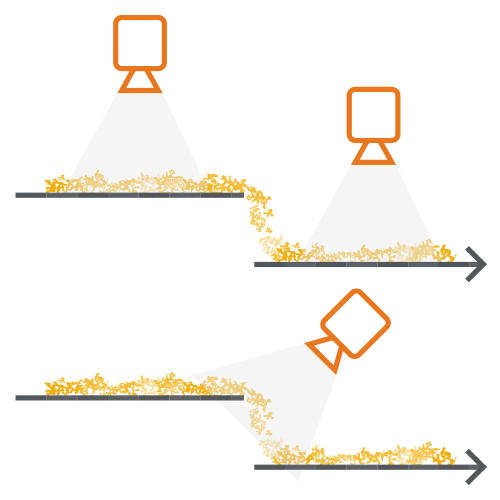

During transport on conveyor belts, sources of danger move quickly from one position to the next. In the area of delivery and removal, false alarms can be caused by exhaust gases and exhaust pipes from vehicles. In storage, static sources of fire and bulk goods are particularly dangerous. In processing, danger is mainly due to mechanical action or movement, e.g. during unpacking, shredding, shaking, separating or pressing.

Many causes are not immediately recognizable in recycling plants. Even small ignition sources can quickly have major effects. Numerous disturbance variables make detection difficult. The powerful and robust ADICOS fire detectors are particularly suitable for these applications. Thanks to their high response speed, infrared fire detectors from the HOTSPOT series are ideal for detecting moving parts, e.g. on the conveyor belt directly after shredding. Dangerous parts such as heated batteries are discovered quickly and can therefore be removed in good time. Fire gas sensors of the GSME series are also used. They notice open fires and smoldering fires and are able to differentiate between disturbing but harmless gases from dangerous, fire-characteristic gases.

Industrial Fire Detection ADICOS